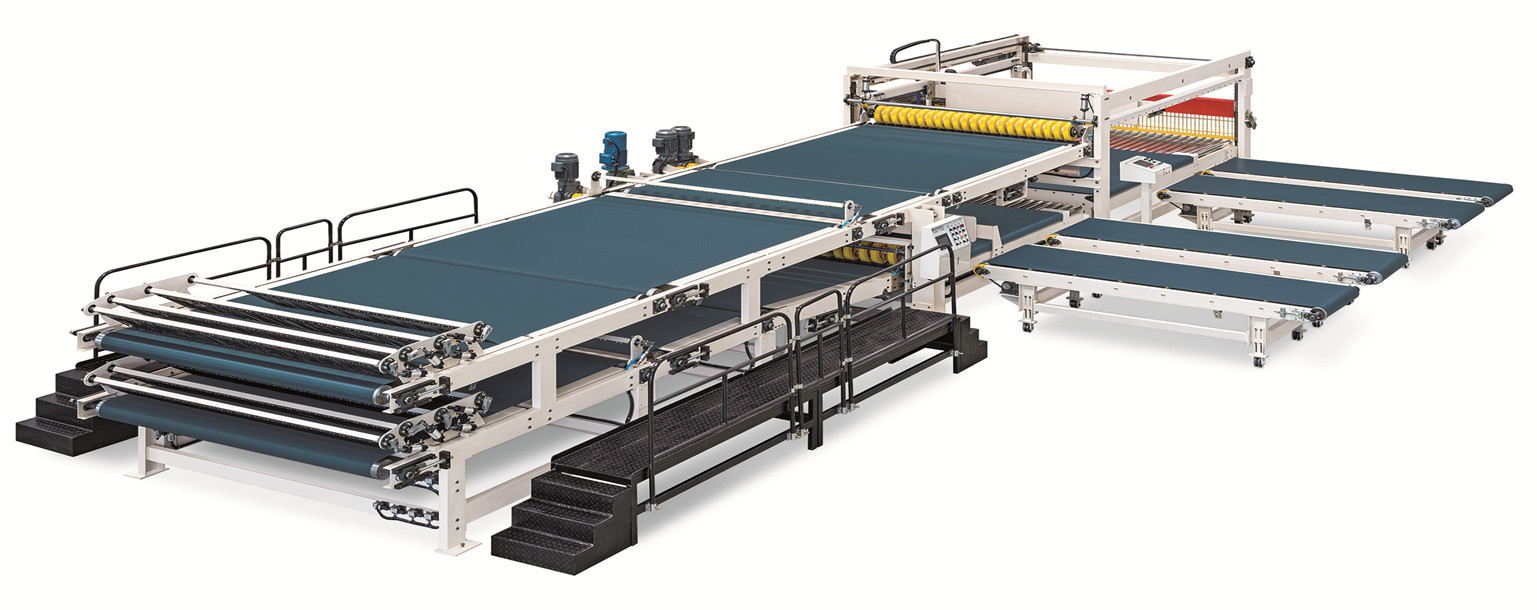

This machine is used for board arrangement, overlapping conveying,stacking and transverse discharge completed at late segment of production lines. It could be able to match with high and mid-speed corrugated paper production lines, realize automatic counting with computer and automatically separate stacks based on preset number of each stack and precisely change the order automatically.

Electric & Pneumatic part

Servo motor and VF motor

Pneumatic components from SMC, Air Tac

Actuation Part

High quality hot-rolled channel steel frame

Conveying roller made of high-quality seamless steel tube and precisely drawn

steel pipes which are subject to dynamic balance checking;

Switzerland Rapplon conveying belt

Transmission Part

Imported synchronous belt

HRB precision bearing

Imported coupling

Control Part

Lifting control of suspension basket platform: servo motor

Conveying control of conveying segment: Schneider frequency converter

Control of rear baffle: Quickly positioning controlled by servo motor

Lift Control: Servo accurate calculation

Operation Monitoring: Schneider touch screen

Monitoring Control: Schneider PLC, PEPPERL FUCHS proximity switch,

optoelectronic switch

Low-voltage Apparatus: Schneider

The upper layer uses four-segment flat belt for board conveying and lower layer uses three

segment flat belt for board conveying which are both controlled synchronously with production line

speed and both could have its speeds automatically adjusted during stack change or order change

to ensure smooth and reliable operation

Upper layer and lower layer are operated separately, so that two specifications of boards can be

stacked at the same time.

The board feeding end of upper and lower layers uses four groups of carbon fiber paper pressing

brush for paper pressing and adjusts the pressing based on length of boards. A pneumatic board

supporting board and a pneumatic board pressing steel belt are arranged between the two rear

conveying segments of the upper and lower layers, so as to automatically control the lifting,

automatically and reliably separate boards while stacks and orders are changed.

The suspension basket stacking of upper layer and gantry type stacking of lower layer both are

controlled by servo motor to ensure stable lifting.

The flat belt type stacking and transverse discharge functions used by upper and lower layers

could ensure the boards are stably output when a preset number of stacking is reached.

The position of rear baffle could be automatically adjusted by AC servo motor to realize fast order

change and effective output of boards.

The laser distance-measuring device could accurately measure stacking height.

With motorized trolley, the boards that transversely discharged are output quickly. In case of no

motorized trolley, conveying and packing platform will be provided.

The paper conveying strap uses special tensioning device which could be adjusted easily and

serve for long service life.

Operation monitoring of gantry type stacker’s touch screen is achieved easily and visually.